Unlike Any Other Recreational Trailer In The World

Born from humble beginnings, Airstream is the creation of a man named Wally Byam. Wally was born on the Fourth of July, just one generation removed from a pioneering family who made a new life where the wheel ruts of the Oregon Trail came to an end. From this seed, planted in American soil, grew a legend. Shortly after founding Airstream Trailers, Inc. in 1931, Wally constructed his first riveted aluminum shell trailer. Many of those original trailers are still on the road today. Over the next 85 years, countless innovations followed. But since the beginning, Airstreams have been built with the same obsessive attention to detail.

No Shortcuts On Quality

Airstreams are unlike any other recreational trailer in the world, and it’s not just because of their legendary history or passionate community of owners. It’s also because they’re constructed under a single roof in Jackson Center, Ohio, built by hand under the watchful supervision of expert craftspeople – many of whom have worked for the company for decades.

Building The Foundation

Airstream Travel Trailers are iconic, treasured, and passed from generation to generation. Today, they carry on Wally’s legacy – his vision of high adventure, his pride in quality, and his spirit of innovation. And they’re true to his promise: “to make your travel dreams come true.” What follows in this guide is the story of how they’re made, and why every detail of that process is so important. In this section, you’ll read about the chassis and other components that form the solid foundation on which an Airstream Travel Trailer is built.

It Starts With The Chassis

Every component of an Airstream Travel Trailer offers the ideal combination of light weight and maximum strength. The chassis, which is built separately from the exterior shell, is no different. And that’s where it all begins. Each Airstream features a chassis built unlike any other – a ladder-frame steel, free-standing, self-supporting chassis. Welded steel outriggers are utilized for additional support and strength, and the chassis has a corrosion-resistant coating.

A Smooth Ride

Next, the axles are constructed and added to the chassis. All Airstream Travel Trailers feature a premium rubber torsion suspension system that offers a number of advantages when compared to the industry-standard spring axle. Airstream has been using torsion for more than 50 years. And each wheel has its own suspension, absorbing 50% more road vibration and reducing wear and tear on tires and other components. This virtually eliminates flexion in crosswinds, and because the suspension reduces leaning during turns, the overall towing experience is smoother.

Airstream Suspension

Airstream’s torsion suspension system compare to a traditional suspension? It offers far better handling than the standard spring axles found in most other trailers, which have a higher center of gravity and are more likely to rust over time. Airstreams can even be taken over rough terrain – a big reason why they’ve seen more of the world than any other brand. And thanks to the independent suspension, multi-axle models can be towed on a flat tire over short distances at a slow speed.

A Low Center Of Gravity

With the chassis ready to go, it’s time to build the superstructure. And that starts with the floor. Each Airstream is built from the bottom up, similar to a house. The floor is made from WBP, 5/8”-thick tongue and groove wood with an antiwicking seal applied to the edges.

Because the holding tanks are built into the chassis frame, more than half the Airstream’s total weight is below the floor line. Why’s that so significant? A low center of gravity means greater stability and smoother towing.

Every Airstream floor plan maximizes functionality and comfort, and offers the most even weight distribution possible. It all starts at the bottom.

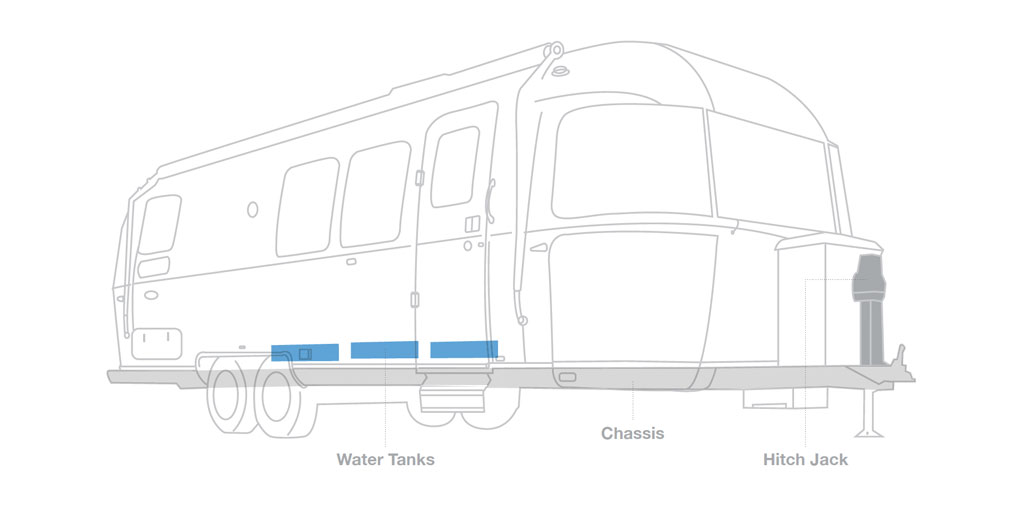

Completing The Chassis

By now, the chassis assembly is nearly finished. Next, the main water tanks and dump valves are insulated and installed. Finally, the hitch jack, sub-floor plumbing, and heat ductwork (which warms water tanks to help prevent freezing) are added. Every Airstream floor plan maximizes functionality and comfort, and offers the most even weight distribution possible. It all starts at the bottom.

Building The Shell

Do you remember the first time you ever saw an Airstream? The iconic, gleaming silver exterior makes them not only memorable, but also instantly recognizable. But do you know why they’re built that way? In this section, you’ll learn how the main structure is riveted together from individual pieces of aluminum – and why we do it that way.

That Iconic Shape

Wally Byam named his creation Airstream “because that’s the way they travel, like a stream of air.” That iconic shape isn’t just part of their charm: An Airstream’s aerodynamic, lowprofile shape naturally delivers low wind resistance, creating less drag. Side winds are almost unnoticeable, and the rounded end-shells make them easier to control even in heavy winds.

Another advantage? Owners also experience between 20 and 30 percent savings in fuel costs, due to the efficiency of towing.

Built With Purpose

The shell comes next. Each Airstream uses an average of 1,200 square feet of strong, lightweight, coated aluminum. It’s all treated with materials that resist ultraviolet rays, mold, discoloration, cracking, flaking, and pulverization. Reflective white enamel on the roof further reduces interior temperatures by up to 7°F.

Every single piece of aluminum has a purpose. A CNC router cuts openings in the aluminum sheets, templated for later installation of windows, the door, wheel wells, water fill doors, furnaces, water heaters, and access doors.

Absolutely Riveting

With each section selected and cut, it’s time to piece it all together. The primary shell segments, which are individually stretch-formed and trimmed from aircraft-grade aluminum, are hand-riveted to the aluminum structural ribs.

An average of 3,000 rivets is used to build each Airstream. While labor intensive, it’s done with great care to avoid denting or otherwise weakening the aluminum. Riveting partners cannot see or hear each other: one is on the outside with a rivet gun, and the other is inside with a bucking bar to flatten each rivet.

A Monocoque Shell

An Airstream and an airplane’s fuselage are built similarly, as if constructed to take flight. Why? The outer skin is built to absorb almost all the stress exerted on the trailer’s body, offering superior structural integrity and protecting vital components, both inside and out.

This is called a “semi-monocoque” structure. All its separate components are pieced together in such a way that they becomes what’s essentially one solid, unified shell. That means a finished Airstream is extremely durable, while remaining lightweight.

I Can See Clearly

Now that the exterior shell is nearly finished, it’s time to install the windows. Each one is built in an extruded aluminum frame, both for a clean appearance and superior durability. The windows are placed in the previously cut holes and secured with more rivets.

Airstream windows are made from thick tempered glass that’s bonded to the frame using polyurethane to eliminate the risk of leaks. Each window that opens has a built-in gutter above the glass to divert rain.

Next, another craftsman seals the interior seams. And at last, the whole exterior shell is complete and ready to be affixed to the chassis.

Completing The Exterior

In the next phase of construction, the completed outer shell is securely connected to the chassis. Then, the Quietstream™ ducted climate control system is installed. And before any work can begin on the interior, each Airstream undergoes extensive quality checks in our special water testing bay. This ensures the shell and chassis are in perfect condition for the next step of the manufacturing process.

A Solid Connection

The entire semi-monocoque exterior shell is lifted with a crane, lowered onto the chassis, and securely bolted. No other recreational trailer on the market can be lifted by its roof – a true testament to the strength of the aluminum superstructure.

As this is done, wiring is threaded into the shell. The wooden floor is also firmly screwed onto the chassis. The shell and chassis are now permanently joined, but there’s still plenty of work to be done before the Airstream is finished.

Cool Summer

Next comes the roof air conditioner. Quietstream™, Airstream’s ducted climate control system, is now standard on all Travel Trailers except for the Sport. Quietstream™ effortlessly cools the cabin within minutes, and it does so in relative silence. So instead of listening to a groaning, clattering air conditioner, you can relax in comfort.

Quietstream™ even features a heat pump, an electric element that pulls ambient heat from the air and transfers it to the coils, heating the trailer without using the furnace. Drip tubes drain any condensation and empty it under the trailer, so water doesn’t trickle down the roof like on most recreational vehicles.

Test Chamber

Once the exterior is completed, every Airstream must pass a rigorous water test before proceeding down the line. In a special testing bay, 88 high-pressure spray nozzles blast the exterior with more than 10,000 gallons of water – and not just for a few seconds, but for 30 minutes.

All the while, a technician is inside checking for leaks. In the rare event a leak is detected, it’s fixed right away, and the exterior shell is completely retested before moving down the line. The water that blasts each Airstream is recycled through massive filters before being reused for the next test.

Installing The Insulation

After an Airstream passes the hurricane test, the interior is sprayed with a water-based adhesive, and the insulation is installed. Knauf EcoBatt® insulation with ECOSE technology is made from 61.9% postconsumer recycled content, combining renewable materials like sand and recycled bottle glass with a revolutionary new bio-based bonding agent.

Among the safest types of insulation available, EcoBatt® is certified for use in nursing homes, hospitals, schools, and daycares, and contains no phenol, formaldehyde, acrylics, or artificial colors. And, of course, its outstanding insulation value means it will keep you warm in cold temperatures.

Building The Interior Shell

Next, the interior superstructure is assembled, using the same high-strength aluminum found on the exterior. The inner shell is riveted to the aluminum bows and ribs of the primary framework.

Once the aluminum is trimmed for window and door openings, an insulating vinyl wall liner is glued to the interior skin to form a barrier against extreme temperature changes, which prevents condensation.

Thermal barrier bonding tape is also applied between the interior and exterior skins to reduce temperature transfer.

After the interior shell is complete, an inspector uses a high-voltage electrical device to check all electrical outlets and connections before the furniture and appliances are installed. All plumbing and tanks are also inspected using high-pressure air to ensure the system doesn’t have any leaks.

Feels Like Home

Flooring is laid, put into place, and cleaned. Then the bathroom is built. The shower’s fiberglass shell – one complete piece – is installed, a hole is cut for the drain, and the plumbing is connected. Next, the lavatory cabinet, toilet assemblies, and final shower components are added.

Every Airstream bathroom features ample storage, stainless steel faucets, quality fixtures, and flooring and surfaces that are easy to maintain and clean.

Kick Back And Relax

Every Airstream is custom-fit with handcrafted furniture that’s been assembled in the wood shop at our production facility in Jackson Center, Ohio. We use only high-quality Italian Lite- Ply or hardwood – you won’t find particle board in any trailer – and everything is built as solid-wood assemblies, just like household cabinetry.

All cabinetry, wardrobes, and furniture are designed specifically for each model, meaning you won’t find Flying Cloud furniture in the Classic. Once constructed, the wood panels, frames, drawers, solid wood trim, and Corian® countertops are sanded, glued, and finished. Then, any raw wood is stained and finished – not just because it looks nicer, but because it’s easier to clean and will last longer, too.

Only One Way In

As you learned, Airstream’s outer shell is fully completed before any furniture, cabinetry, plumbing, and electrical systems are installed. Every component fits through the 26”-wide door, which takes eight hours to manufacture and is built in-house from high-strength aluminum. After it’s been carefully riveted into place, it seals tight, like a bank vault.

This is a huge reason why vintage Airstreams are so popular. Airstream travel trailers carry the highest resale value in the industry, and that’s not just because they’re durable enough to last a lifetime. It’s also because every component in an Airstream fits through the door. That means any maintenance or renovations can be taken care of without taking apart the entire travel trailer.

Drifting Off In Comfort

Next, all bedroom furniture is installed. Airstream uses only comfortable pillowtop memory foam mattresses, and they’re custom-shaped to fit the contours of the travel trailer.

Most Airstream bedrooms are also outfitted with a large custom-built wardrobe, USB and 110V outlets, and entertainment options like a television and sound system.

Smells Like Home

Many Airstreamers love to cook, and our galleys are built with this in mind. Every Airstream Travel Trailer contains a complete kitchen that’s designed for maximum convenience and efficiency. Kitchens include residential-grade appliances, pantries, water purifiers, stainless steel sinks, and storage for pots, pans, and utensils. Each of these components is installed as the finishing touches are put on the new Airstream.

Finally, lounges, chairs, dinette cushions, curtains, and window shades are installed.

Ultraleather™ And Spradling

It wouldn’t be your home on the road without comfortable furniture to relax on, which is why Airstream uses either Ultraleather™ or Spradling materials in all seating environments. The fabrics from Ultraleather™ and Spradling are durable, breathable, stain-resistant, and engineered for years of comfortable enjoyment.

They also resist temperature change, so they won’t crack because of cold weather.

Quality Assurance

Our new Airstream is just about ready to hit the road – but first, it will undergo extensive quality testing.

Before any Airstream leaves the production line, our Quality Control team performs a series of detailed tests. They’ll look closely at the overall cosmetics of the trailer, make sure all systems are working properly, and test all interior and exterior parts.

Other tests include pressure-checking the LP gas system, filling the drain system to check it for leaks, pressurizing the water system, testing the tank monitoring system, heating the furnace, and cooling the refrigerator. Finally, the interior and exterior are thoroughly cleaned, and a fresh coat of wax is applied by hand. Only then is the travel trailer ready to leave Jackson Center for an authorized Airstream dealer – and, eventually, its new home!

The Airstream Warranty

They’ve always been made to last. That’s why over 75% of all Airstream Travel Trailers ever built are still on the road today.

Wally’s dream was to connect ordinary people to the excitement of travel, to take them to new and faraway places without sacrificing the comforts of home. While we strive for perfection, we caution new owners to treat their Airstream just like they’d treat a new home.

Even after extensive quality testing, there’s a chance you may experience minor issues with your new travel trailer – after all, it contains so many complex systems. But we’ll always place our customers first, which is why we back all new Travel Trailer sales with three-year Trailer, Structural, and Major Component Warranties.